Manufacturing

There's Nothing We Can't Do

Open capacity %

Process tanks

Cranes

We offer several in-house special chemical processing options with one of the country’s largest fully integrated in process anodizing lines. Anodizing is an electrochemical process that converts aluminum’s metal surface into a decorative, durable, corrosion-resistant, anodic oxide, shiny and/or colorful finish. Anodizing allows the aluminum to maintain its metallic appearance. We offer clear anodizing, which does not incorporate any pigments, along with black, red, grey, bright dip clear and other specialty color combinations upon request.

SPECS

- Fully automated aluminum anodizing line with two anodize tanks with 22V 4,500 Amp rectifiers.

- Offering the following dyes: Red, Black and Grey

- Pretreatments Available: Acid Etching (Fluoride Etch), Caustic Etch, Chemical Polishing (Bright Dip)

- Finish meets or exceeds the following specifications: MIL-A-8625F Type II, ASTM B580, ASTM B136 and ASTM B680

- Working volume of process tanks: 72”x60”x24”

Laser Hoist positioning system:

- 3 Fully automated rail rider hoist system

- Stainless steel or Polypropylene Tanks

- Titanium or Aluminum racking available

- Air Knife Assist Dryers

- Hot water boiler system (including backup boiler)

- Integrated software providing full traceability for all processing parameters

- On site laboratory providing solution analysis and material testing

- DI polished RO water used for all process tanks

- Inspection equipment including Eddy Current thickness tester, Sphere Spectrophotometer, Multi Angle Gloss meter

- Air cooled scroll chiller

- >50,000 CFM Push-Pull Ventilation and Scrubber system

- On site waste water system

LISSMAC SURFACE SANDING MACHINES

Open capacity %

Machines

Perfect surface finish using the dry grinding process. The SMD5 is built according to the modular principle and can be individually configured to meet customer requirements and is characterized by low tool costs, simple handling and also by the cost effective price-performance ratio which results in short amortization times.

SPECS

- Number heads 2

- Compressed air 6.0 bar (87 psi)

- Abrasive belt length 1900 mm (75 inch)

- Working width 1350 mm (53)

BURRKING PERIPHERIAL BRUSHING MACHINES

Open capacity %

Machines

At our facility, your metals will never be dull. Brushed or dull polished metal is metal with a unidirectional satin finish. It is produced by polishing the metal with a 120–180 grit belt or wheel then softening with an 80–120 grit greaseless compound or a medium non-woven abrasive belt or pad to make the metal shine in any direction needed, the same way we like to make our customers shine.

SPECS

- 60″ belt up to 2-1/2″ wide

- 8000 SFPM belt speed

- Variable speed 120/220-1 HP

BALDOR METAL POLISHING MACHINES

Open capacity %

Machines

Polishing aluminum is a challenging undertaking. We use a sensible and methodical approach that yields rewarding results. We have many options, variations, and preferences that distinguish our polishing approach from others. We employ the use of buffing wheels as primary components and developed our own craft “secrets” based on our 20+ years of polishing experience.

SPECS

- Number heads 2

- Maximum part diameter 15”

- Maximum part length 40”

- Polishing belt diameter 18”

- Working width 24”

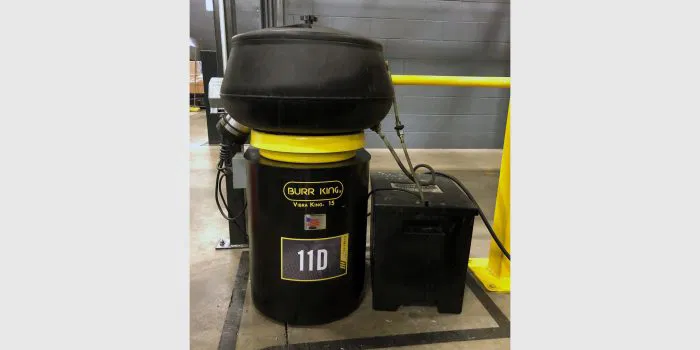

BURRKING VIBRATORY DEBURRING MACHINE

Open Capacity %

Machine

Our unique additional add-ons in the facility put special finishing touches required to complete the parts to perfection. The Burr King vibratory/polishing deburring system is high energy, fast processing speeds.

SPECS

- Total volume cu. feet 1.3

- Working volume cu. feet 1.0

- Bowl diameter inside inches 17.5”

- Bowl depth inside 9.5”

- Part length max. inches 12”

- Part width max. inches 5.5”

- Load max. lbs. 150

- Horse Power 1/2RPM

- 1725Volt/Phase 115/1