Manufacturing

There's Nothing We Can't Do

- PLANT VIEW

- OKUMA HORIZONTAL MB8000H FMS

- OKUMA HORIZONTAL MA600H FMS

- OKUMA HORIZONTAL MB4000H FMS

- OKUMA HORIZONTAL MB4000H PALLET ACE

- OKUMA VERTICAL MB66V

- HAAS VERTICAL VF7

- HAAS VERTICAL VF6SS

- HAAS VERTICAL VF4SS

- HAAS VERTICAL VF2SS

- MULTUS LATHE MULTI-TASKING U4000BB WITH ROBOTICS

- OKUMA LATHE LB3000EX WITH ROBOTICS

- TSUGAMI SWISS BO385

- TECHNIKS SHRINK PRO SYSTEM

- ZOLLAR SMILE 600-4 TOOL PRESETTER MACHINE

- BYSTONIC BYSPEED LASER 3015 5200 WATT

- BYSTRONIC BEYELER PR 60 IPC BRAKE PRESS

- BAYKAL FAB-LINE APHS 2100 x 300 BRAKE PRESS

- ADAPTIVE MOTION 3D PIPE BENDING MACHINE

- MILLER DYNASTY 700 TIG WELDING MACHINE

- MILLER DYNASTY 350 TIG WELDING MACHINES

- METAL SAW

- BURRKING VIBRATORY DEBURRING MACHINE

- BURRKING PERIPHERIAL BRUSHING MACHINES

- LISSMAC SURFACE SANDING MACHINES

- BALDOR METAL POLISHING MACHINES

- PRICE KOCH ANODIZING LINE

- FOBA LASER MARKING SYSTEM

- ZEISS ACCURA COORDINATE MEASURING MACHINE

- FACTORY AUTOMATION - CONVEYOR SYSTEM

- KARDEX REMSTAR SHUTTLE XP AUTOMATED STORAGE AND RETRIEVAL SYSTEM

- MURATEC AUTOMATED STORAGE AND RETRIEVAL SYSTEM

CNC Machines

Team members

Open Capacity %

What began with one single CNC machine and a single employee in 1995 has expanded to some 200 machining tools and a team of more than 130 working in our world class 160,000 square foot facility.

OKUMA HORIZONTAL MB8000H FMS

This horizontal machining center provides highly-accurate, high-speed machining for large parts up to 2000 pounds with integrated tooling. For heavy large parts with high production or low lot size jobs – flexible, strong, accurate, productive.

Open capacity %

Current OEE %

Lights out hrs. capacity

SPECS

- 800 mm square pallet

- Axis travels X: 1,400, Y: 1250, Z: 1,250 – 4 axis

- 50 Taper 12,000 RPM, 40/30 HP VAC Spindle

- 2-speed range integral motor-spindle

- 1 degree B axis rotary table

- 12 second rotary APC change (180 degree)*

- ATC: T-T : 2.0 sec, C-C: 4.4 sec.*

- 2,362 IPM rapid ( 60 meter/ min )

- 0.7 G – Maximum acceleration

- Y-axis motor bracket cooling

- Spindle head cooling

- 281 Tool matrix magazine

- 1000psi through-the-tool coolant

- 12 position pallet pool

OKUMA HORIZONTAL MA600H FMS

The most incredibly versatile pallet-based FMS system that integrates with six OKUMA MA-600 Horizontal machining centers, allowing up to 84 hours of true lights out manufacturing including integrated tooling, material storage, and handling. System is highly flexible and can process large variety of parts, sizes and volumes. This FMS system is the largest deployment in North America.

Open capacity %

Current OEE %

Lights out hrs. capacity

SPECS

- 630 mm square pallet

- Axis travels X: 1,000, Y: 900, Z: 1,000 – 4 AXIS

- 50 Taper 12,000 RPM, 40/30 HP VAC Spindle

- 2-speed range integral motor-spindle

- 1 degree B axis rotary table

- 12 second rotary APC change (180 degree)*

- ATC: T-T : 2.0 sec, C-C: 4.4 sec.*

- 2,362 IPM rapid ( 60 meter/ min )

- 0.7 G – Maximum acceleration

- Y-axis motor bracket cooling

- Spindle head cooling

- 285 Tool matrix magazines

- 1000psi through-the-tool coolant

OKUMA HORIZONTAL MB4000H FMS

The most incredibly versatile pallet-based FMS system that integrates with six OKUMA MB4000 Horizontal machining centers, with integrated tooling, material storage and management, allowing up to 60 hours of true lights out manufacturing. System is highly flexible and can process a large variety and volume of small and mid-size parts.

Open capacity %

Current OEE %

Lights out hrs. capacity

SPECS

- 400 mm square pallet

- Axis travels X: 22.05, Y :22.05, Z:24.61 – 4 axis

- 40 Taper 15,000 RPM, 35 HP VAC Spindle

- 2-speed range integral motor-spindle

- .001 degree B axis rotary table

- 7 second rotary APC change (180 degree)*

- TC: T-T :1.0 sec, C-C: 2.3 sec.*

- 2362 IPM rapid ( 60 meter/ min )

- Y-axis motor bracket cooling

- Spindle head cooling

- 218 Tool Matrix Magazines

- 1000 psi coolant

OKUMA HORIZONTAL MB4000H PALLET ACE

The most incredibly versatile pallet-based FMS system that integrates with two OKUMA MB4000 Horizontal machining centers with integrated tooling, allowing up to 48 hours of true lights out manufacturing. System is highly flexible and can process a high volumes of small and mid-size parts.

Open capacity %

Current OEE %

Lights out hrs. capacity

SPECS

- 400 mm square pallet

- Axis travels X: 22.05, Y :22.05, Z:24.61 – 4 axis

- 40 Taper 15,000 RPM, 35 HP VAC Spindle

- 2-speed range integral motor-spindle

- .001 degree B axis rotary table

- 7 second rotary APC change (180 degree)*

- TC: T-T :1.0 sec, C-C: 2.3 sec.*

- 2362 IPM rapid ( 60 meter/ min )

- Y-axis motor bracket cooling

- Spindle head cooling

- 218 Tool Matrix Magazine

- 1000 psi coolant

OKUMA VERTICAL MB66V

The Okuma Vertical high-performance machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for high-volume production with reduced cycle times. Highly rigid, thermally-stable construction withstands thermal deformation resulting in reduced thermal growth and improved machining performance.

Open capacity %

Current OEE %

Machines

SPECS

- Travels: X: 59.00” Y: 26.00” Z: 26.11

- 15,000 rpm, 30/25 HP integral motor spindle – standard

- CAT 40 Big Plus 40 V-flange specification

- Spindle jacket cooling system

- Oil air mist spindle bearing lubrication

- Prep for chip conveyor – electrical

- 1,575 IPM, rapid feed X, Y. ( .6, .65 G)

- Z-axis rapid & max. feed-rate: 1,259 IPM

- 48 tool ATC magazine 1.2 sec. T-T; 3.5 sec. C-C*

- 90 gal roll-away twin 0.5 hp coolant system

- Twin chip channel (insulated) with coil conveyors

- 1,000 psi coolant through spindle

HAAS VERTICAL VF7

High spindle speeds, fast rapids, and quick tool changes necessary for high-volume large part production and reduced cycle times with a maximum length of 84 inches.

Open capacity %

Current OEE %

Machine

SPECS

- Travel 84″ x 32″ x 30″

- 40 taper

- 30 hp (22.4 kW) vector drive

- 7500 rpm spindle

- 24+1 station carousel tool changer

- 1000 ipm (25.4 m/min) rapids

HAAS VERTICAL VF6SS

Super-Speed Vertical Machining Center with high spindle speeds, fast rapids, and quick tool changes necessary for high-volume production and reduced cycle times with a maximum length of 64 inches.

Open capacity %

Current OEE %

Machine

SPECS

- Travel 64″ x 32″ x 30″

- 40 taper

- 30 hp (22.4 kW) vector drive

- 12,000 rpm spindle. inline direct-drive

- High-speed 24+1 side-mount tool changer

- 1200 ipm (30.5 m/min) rapids

64″ x 32″ x 30″ , 40 taper, 30 hp (22.4 kW) vector drive, 8100 rpm, inline direct-drive, 24+1 station carousel tool changer, 1000 ipm (25.4 m/min) rapids, power-failure detection module, 1 GB program memory, 15″ color LCD monitor, USB port, memory lock keyswitch, rigid tapping and 55-gallon (208 liter) flood coolant system

HAAS VERTICAL VF4SS

Perfect high-production workhorses. With the high spindle speed, fast rapids, super speed side mount changers and more X, Y and Z axis travel than the VF2SS, it makes for the perfect staple for added capacity and prototyping.

Open capacity %

Current OEE %

Machines

SPECS

- Travel 50″ x 20″ x 25″

- 40 taper

- 30 hp (22.4 kW) vector drive,

- 12,000 rpm, inline direct-drive

- High-speed 24+1 side-mount tool changer

- 1000 ipm (25.4 m/min) rapids

HAAS VERTICAL VF2SS

With the high spindle speed, fast rapids, super speed side mount changers, this makes for the perfect staple for added capacity for parts under 30 inches in length and great for quick turnaround prototyping and production parts.

Open capacity %

Current OEE %

Machines

SPECS

- Travel 30″ x 16″ x 20″

- 40 taper

- 30 hp (22.4 kW) vector drive

- 12,000 rpm inline direct-drive

- High-speed 24+1 side-mount tool changer

- 1000 ipm (25.4m/min) rapids

MULTUS LATHE MULTI-TASKING U4000BB WITH ROBOTICS

The Okuma multi-tasking machining centers includes the main spindle, sub spindle, lower turret and 5-axis head which allows for complete part production without secondary machining steps. Fully outfitted with Westech Gantry loader with automatic Pallet conveyor for extended lights out manufacturing.

Open capacity %

Current OEE %

Machines

SPECS

- Max. turning Ø [mm] 650

- Max. turning length [mm] 1.500

- Spindle speed [min-1] 4.200 [3.000]

- M80 Station ATC magazine – CAPTO C6

- Rapid traverse X-Y-Z [m/min] 50/ 40/ 50

- 1000 psi high pressure

- 12′ bar feeder

OKUMA LATHE LB3000EX WITH ROBOTICS

The Okuma Lathe machining centers includes the main spindle, sub spindle, lower turret which allows for complete part production without secondary machining steps. Fully outfitted with Westech Gantry loader with automatic Pallet conveyor for extended lights out manufacturing.

Open capacity %

Current OEE %

Machines

SPECS

- Ø22.83” swing, Ø13.39” max turn dia.

- 30 HP (22 kW) spindle drive

- 5,000 rpm A2-6 spindle nose

- Hollow cylinder (Main Spindle).Ø3.15 in.

- Through Spindle (Ø80 mm)

- 12 position, 0.1 sec, NC tool turret inch – wedge clamp O.D. tooling

- 1,181 IPM / 984 IPM; Z / X rapid traverse

- Hardened and ground box ways X & Z1,000 psi coolantØ140 flat

- Sub spindle 15/10 HP, 50-6,000 rpm.

- Sub spindle hollow cylinder

- Milling Capacity: 3.7 in3/min

- Milling spindle: 9.5/5.5 hpY-axis +2.76” / -1.97”

- Touch Setter

- FMB Turbo 8-80, 12′ bar feeder

- Bar diameter capacity: 3 mm to 38 mm (.118” to 1.500”)

TSUGAMI SWISS BO385

The Tsugami Swiss Lathe machining centers provide fast cycle times and flexibility with precision suited for part diameters of 1 ¾ diameter and smaller with high production applications. With these sophisticated controls, it streamlines the machining process.

Open capacity %

Current OEE %

Machines

SPECS

- 5-9 axis Swiss Style, Sliding Headstock Lathe

- Tsugami “Double Spindle” Technology holds workpiece firmly, allowing the powerful machine to make deep precision cuts

- Front Tool Post Rotary Tool, Standard with 4 live tool positions

- Rotary Tool Drive for Rear Tool Post improves simultaneous machining capability, live back-working capability

- 20 Tool Positions

- Rapid Traverse Rate of 45 m/min– shortens idle, cycle times

- Fanuc 0i-TD CNC Control

- Automatic loading magazine — 11 linear inches of rack capacity

- 12′ Bar Feeder

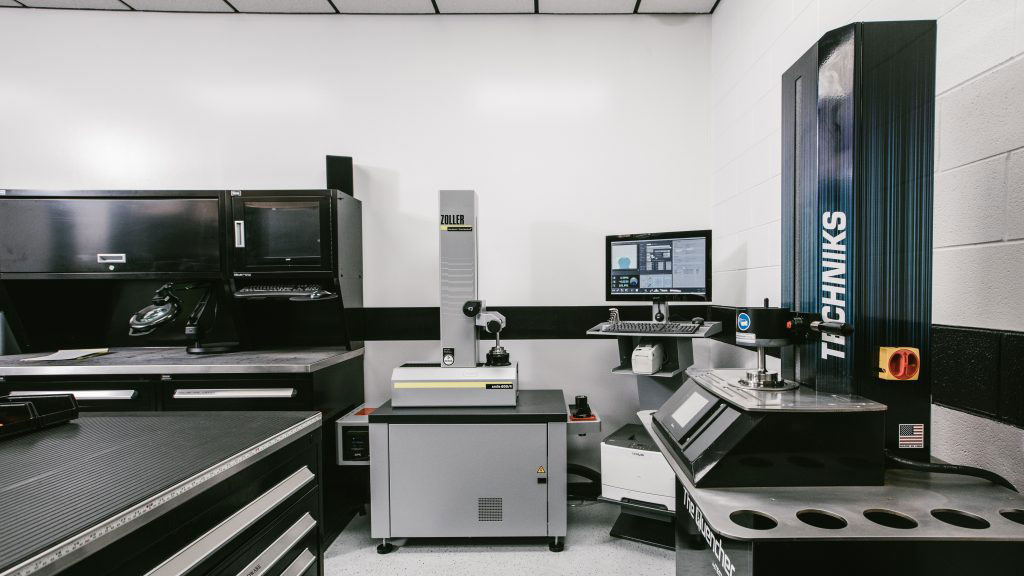

TECHNIKS SHRINK PRO SYSTEM

The ShrinkSTATION is an ideal solution for keeping the tooling and manufacturing process precise every time. It is a reliable shrink fit machine that can handle practically all sizes and types of tool holders.

ZOLLAR SMILE 600-4 TOOL PRESETTER MACHINE

Equipped with all standard measuring functions for professionally presetting and measuring cutting tools.

BYSTONIC BYSPEED LASER 3015 5200 WATT

The Bystronic Byspeed laser system uses precision lasers to cut product with precise specifications. The laser beam is created by the laser source (resonator), conducted by mirrors in the machine cutting head where a lens focuses it at very high power on a very small diameter. This focused laser beam meets the sheet metal and cuts it perfectly to the requested shape.

Open capacity %

Current OEE %

Machine

SPECS

- Bystronic PC Based Controls

- Bystronic5200 Watt Resonator

- High Speed Drives

- Twi 5′ x 10′ Dual Pallet Shuttle Tables

- Non-Contact Cutting Head

- X Axis Travel: 120″, Y Axis Travel: 60″, Z Axis Travel: 3.9″

- Bystronic PC based CNC Control

BYSTRONIC BEYELER PR 60 IPC BRAKE PRESS

This brake press machine gives us the ability to do a large assortment of flexible, high performance, precision metal bending options. It gives us a high positioning and angle precision with high flexibility to produce individual parts, small series and complex jobs, with a large variety of bending tools.

Open capacity %

Current OEE %

Machine

SPECS

- Cybelec Model EVA 12S CNC Control

- Programmable Sheet Lifter

- Dynamic Programmable Crowning

- Hydraulic Upper and Lower Die Clamping

- Programmable controlled Axes (6 Axes)

- Control system: MODEVA 12

- 6 axes

- Pressing force: 60 ton

- Folding length: 2550 mm

- Stroke: 215 mm

- Closing speed: 200 mm/s

- Engine power: 11 Kw

BAYKAL FAB-LINE APHS 2100 x 300 BRAKE PRESS

This brake press machine gives us the ability to do a large assortment of flexible, high performance, precision metal bending options. It gives us a high positioning and angle precision with high flexibility to produce individual parts, small series and complex jobs, with a large variety of bending tools.

Open capacity %

Current OEE %

Machine

SPECS

- Dynamic Programmable Crowning

- Hydraulic Upper and Lower Die Clamping

- Programmable controlled Axes (6 Axes)

- Control system: MODEVA 12

- 6 axes

- Pressing force: 300 ton

- Folding length: 2550 mm,

- Stroke: 215 mm

- Closing speed: 200 mm/s

ADAPTIVE MOTION 3D PIPE BENDING MACHINE

The process of bending metal in the exact direction and angle that fits your application takes exactness and flawless execution. We have the capability with the CNC pipe bending machine to fit complex geometries, angles, rotations, 2D and 3D dimensional bends.

Open capacity %

Current OEE %

Machine

SPECS

- EB-100 epa, cnc pipe bender

- Blazing fast bending, 180 degrees in 1 second

- Quad stack, mount 4 stacks of full size tooling

- Draw bend, push roll, or both

- Low-interference bend head & swing arm

- 4″ capacity up to 24′ bars

MILLER DYNASTY 700 TIG WELDING MACHINE

Powerful and compact power source capable welding machine perfect for a variety of high demand applications including: precision metal fabrication, heavy manufacturing, maintenance and repair, pipe and tube manufacturing, aerospace, tool and die, and TIG Automation. It can weld up to 1″ aluminum.

SPECS

- Industrial Applications

- Precision fabrication

- Heavy fabrication

- Pipe and tube fabrication

- Anodized aluminum fabrication

- Processes TIG (GTAW), Pulsed TIG (GTAW-P), Stick (SMAW), Air Carbon Arc (CAC-A),

- 700: 3/8-in. maximum

MILLER DYNASTY 350 TIG WELDING MACHINES

Powerful and compact power source capable welding machine perfect for a variety of high demand applications including: precision metal fabrication, heavy manufacturing, maintenance and repair, pipe and tube manufacturing, aerospace, tool and die, and TIG Automation. It can weld up to 1/2″ aluminum.

SPECS

- Industrial Applications

- Precision fabrication

- Heavy fabrication

- Pipe and tube fabrication

- Anodized aluminum fabrication

- Processes TIG (GTAW), Pulsed TIG (GTAW-P), Stick (SMAW), Air Carbon Arc (CAC-A)

- 350: 1/4-in. maximum

METAL SAW

The CS2 is one of the fastest, most accurate fully-automated cutoff saws on the market for non-ferrous extrusions. It handles materials from ¼” to 12” thick with a cutting window of 24”. The short cutting window allows a tight level of cutting accuracy. The standard back gauge supports materials from 12’ to 24’ in length. Metal Saw system is outfitted with 24’ bar feed loaders.

.

Open capacity %

Current OEE %

Machines

SPECS

- Cutting Window 24”

- Cutting Height 1/4” to 12”

- Back gauge Length 12’ to 24’

- Cut Length Range ½” minimum

- Motor 30HP, 22KW

BURRKING VIBRATORY DEBURRING MACHINE

Our unique additional add-ons in the facility put special finishing touches required to complete the parts to perfection. The Burr King vibratory/polishing deburring system is high energy, fast processing speeds.

SPECS

- Total volume cu. feet 1.3

- Working volume cu. feet 1.0

- Bowl diameter, inside inches 17.5”

- Bowl depth inside 9.5”

- Part length max. inches 12”

- Part width max. inches 5.5”

- Load max. lbs. 150

- Horse Power 1/2

- RPM 1725

- Volt/Phase 115/1

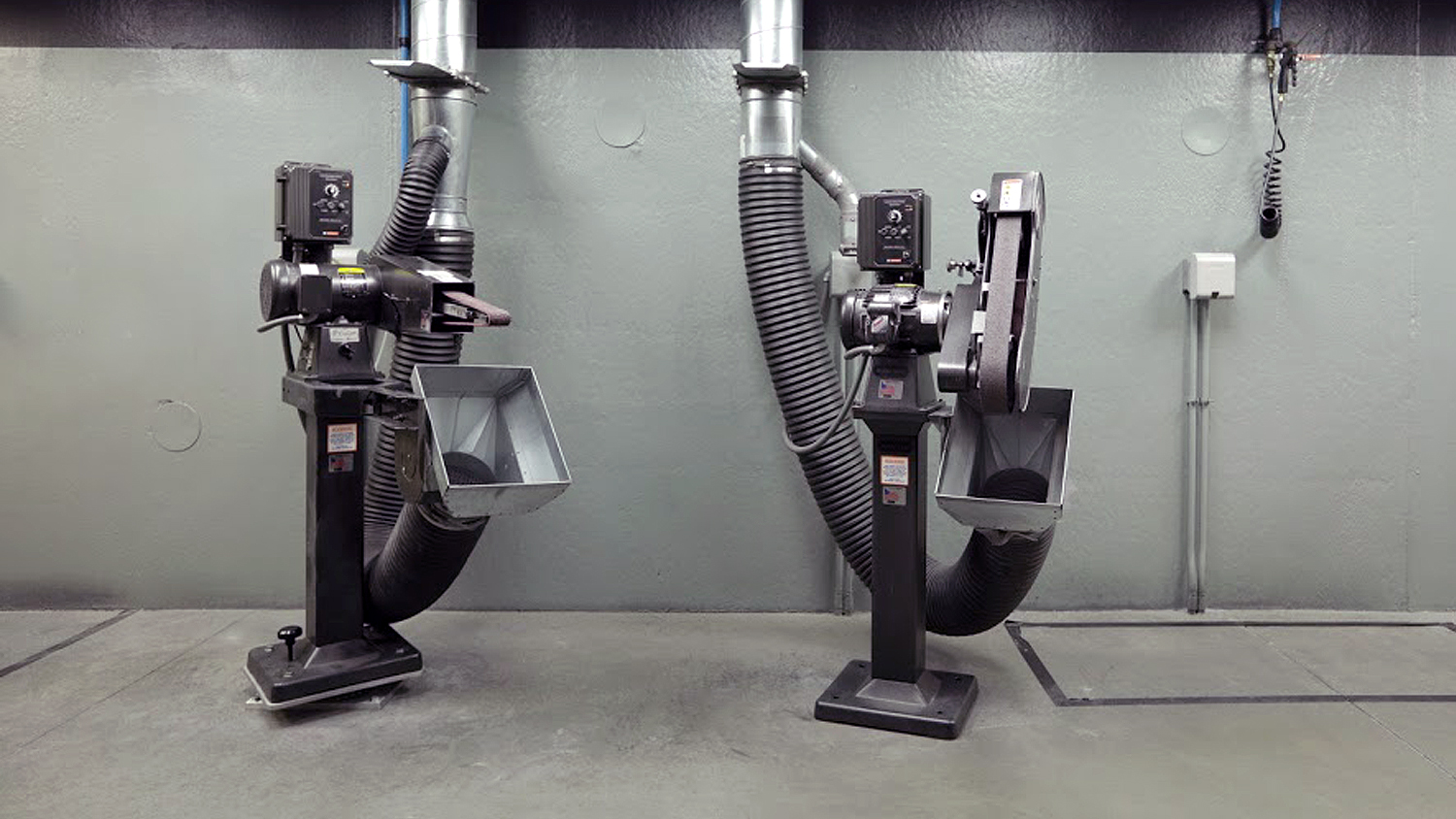

BURRKING PERIPHERIAL BRUSHING MACHINES

At our facility, your metals will never be dull. Brushed or dull polished metal is metal with a unidirectional satin finish. It is produced by polishing the metal with a 120–180 grit belt or wheel then softening with an 80–120 grit greaseless compound or a medium non-woven abrasive belt or pad to make the metal shine in any direction needed, the same way we like to make our customers shine.

Open capacity %

Current OEE %

Machines

SPECS

- 60″ belt up to 2-1/2″ wide

- 8000 SFPM belt speed

- Variable speed 120/220-1 HP

LISSMAC SURFACE SANDING MACHINES

Perfect surface finish using the dry grinding process. The SMD5 is built according to the modular principle and can be individually configured to meet customer requirements and is characterized by low tool costs, simple handling and also by the cost effective price-performance ratio which results in short amortization times.

Open capacity %

Current OEE

Machines

SPECS

- Number heads 2

- Compressed air 6.0 bar (87 psi)

- Abrasive belt length 1900 mm (75 inch)

- Working width 1350 mm (53)

BALDOR METAL POLISHING MACHINES

Polishing aluminum is a challenging undertaking. We use a sensible and methodical approach that yields rewarding results. We have many options, variations, and preferences that distinguish our polishing approach from others. We employ the use of buffing wheels as primary components and developed our own craft “secrets” based on our 20+ years of polishing experience.

Open capacity %

Current OEE %

Machines

SPECS

- Number heads 2

- Maximum part diameter 15”

- Maximum part length 40”

- Polishing belt diameter 18”

- Working width 24”

PRICE KOCH ANODIZING LINE

We offer several in-house special chemical processing options with one of the country’s largest fully integrated in process anodizing lines. Anodizing is an electrochemical process that converts aluminum’s metal surface into a decorative, durable, corrosion-resistant, anodic oxide, shiny and/or colorful finish. Anodizing allows the aluminum to maintain its metallic appearance. We offer clear anodizing, which does does not incorporate any pigments, along with black, red, grey, bright dip clear and other specialty color combinations upon request.

Open capacity %

Process tanks

Cranes

SPECS

- Fully automated aluminum anodizing line with two anodize tanks with 22V 4,500 Amp rectifiers.

- Offering the following dyes: Red, Black and Grey

- Pretreatments Available: Acid Etching (Fluoride Etch), Caustic Etch, Chemical Polishing (Bright Dip)

- Finish meets or exceeds the following specifications: MIL-A-8625F Type II, ASTM B580, ASTM B136 and ASTM B680

- Working volume of process tanks: 72”x60”x24”

Laser Hoist positioning system:

- 3 Fully automated rail rider hoist system

- Stainless steel or Polypropylene Tanks

- Titanium or Aluminum racking available

- Air Knife Assist Dryers

- Hot water boiler system (including backup boiler)

- Integrated software providing full traceability for all processing parameters

- On site laboratory providing solution analysis and material testing

- DI polished RO water used for all process tanks

- Inspection equipment including Eddy Current thickness tester, Sphere Spectrophotometer, Multi Angle Gloss meter

- Air cooled scroll chiller

- >50,000 CFM Push-Pull Ventilation and Scrubber system

- On site waste water system

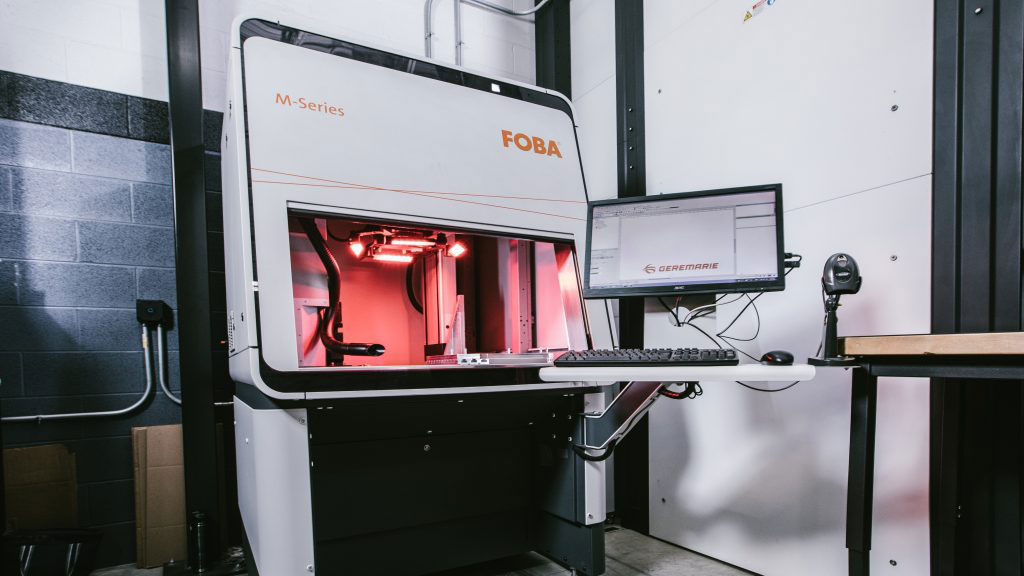

FOBA LASER MARKING SYSTEM

We offer turnkey-ready and customer specific laser processing services. Our laser marking machine adapts and always allows for the most economical and optimal configuration forthe application in question. A variety of loading concepts ensures optimal integration into the production environment, and axis systems can be selected based on the requirements.

Open capacity %

Current OEE %

Machine

SPECS

- M3000-R stations

- 2 position rotary tables

- Programmable Z-axis

- 2 position rotary table with 950 mm (M3000-R) diameter

- Flat part marking up to 10” by 30”

ZEISS ACCURA COORDINATE MEASURING MACHINE

Performance and precision are our top priorities. With its wide range of configurations, the ZEISS ACCURA measuring machine is tailored to meet our customers’ needs and budget. The modular design makes the system futureproof as it can be modified to meet changing requirements on the configuration, sensors and software. If you dream it, we can measure it.

SPECS

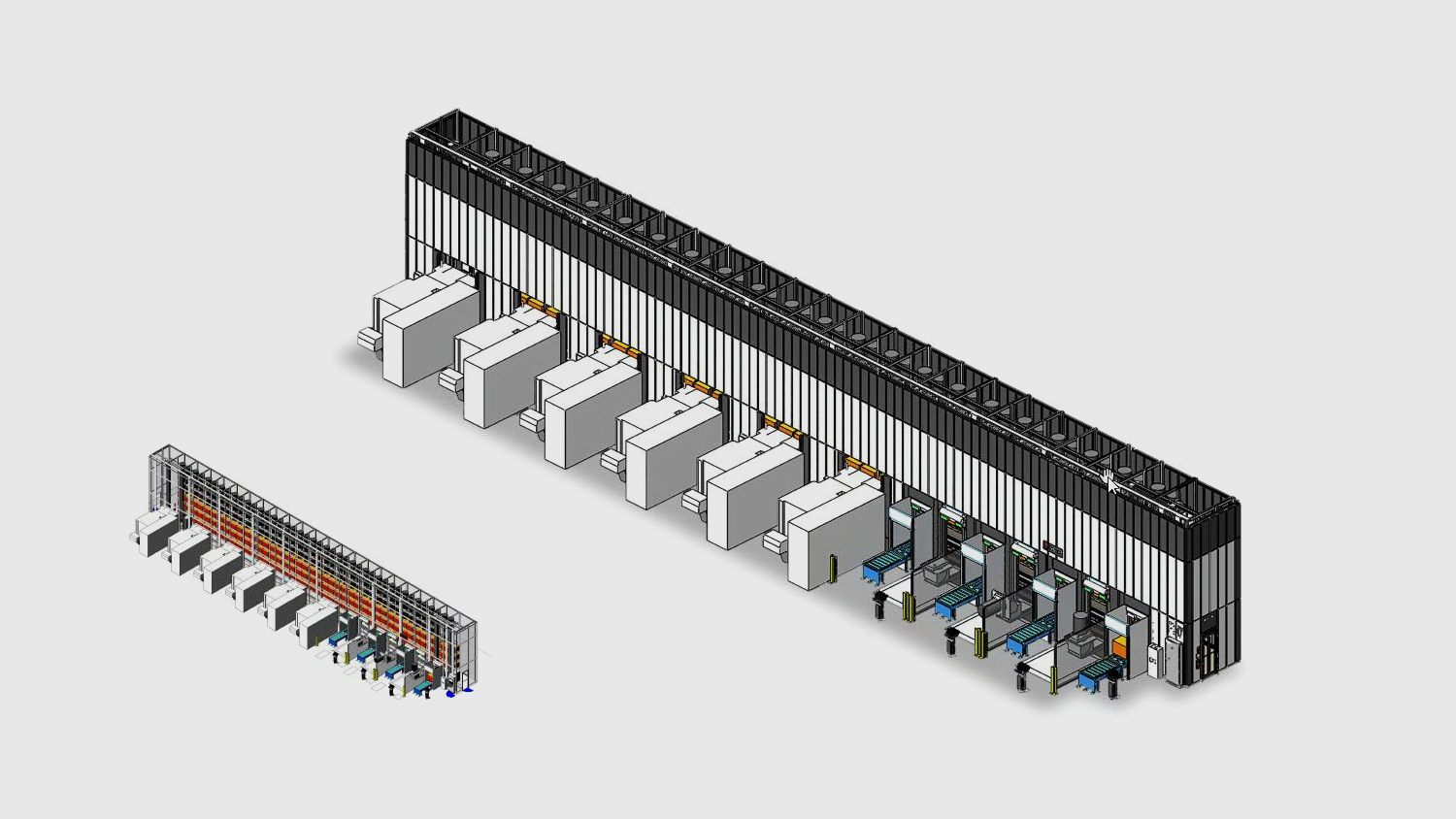

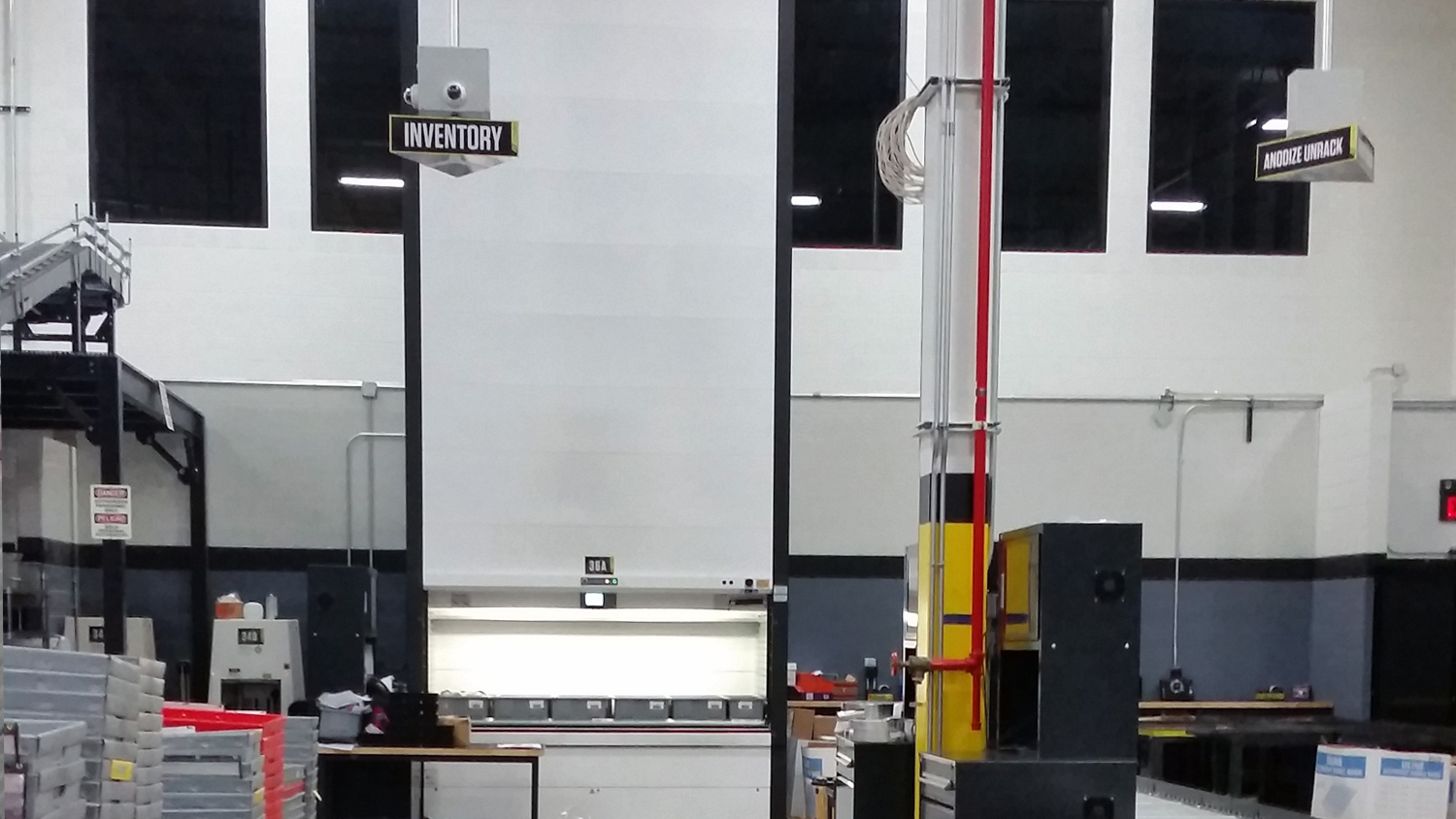

FACTORY AUTOMATION – CONVEYOR SYSTEM

We have over one mile of zero pressure accumulation technology roller conveyors configured to transport all the work in process throughout the plant to each of the necessary processing stations. Once all processes are completed, they are conveyed to the integrated automatic storage and retrieval system.

SPECS

Custom conveyor system, with over a mile of elevated conveyors, fully integrated into the ERP system and process routers, delivers products to and from multiple departments, from operation to operation providing ultimate operating efficiency.

KARDEX REMSTAR SHUTTLE XP AUTOMATED STORAGE AND RETRIEVAL SYSTEM

We have two self-contained inventory storage systems in the facility. The Shuttle XP vertical storage lift system from Kardex Remstar is a highly flexible solution for managing a high number of storage and retrieval applications in a wide range of ways to add to our efficiencies. The cross functional system is fully integrated to our ERP solution allowing for accurate inventory management aligned with Customer needs. The modular design of the Shuttle XP provides virtually unlimited flexibility when making the best use of various part, shelf and room heights. The unit was chosen to perfectly meet our parts capacity and height requirements.

SPECS

- Width 4,460 mm to 7,040 mm

- Depth 2,921 mm to 3,074 mm

- Height 3,050 mm to 20,050 mm

- Unit height pitch 100 mm increments

- Drive speed 250 kg/500 kg

- Vertical speed adjustable up to 1.5 m/s

- Storage/retrieval speed 0,62 m/s

- Horizontal speed adjustable up to 1.3 m/s

- Gross load 30 t per segment

- Tray Width 1,250 mm to 2,450 mm

- Tray Depth 813/864 mm

- Tray spacing min. 75 mm

- Load up to 545 kg

MURATEC AUTOMATED STORAGE AND RETRIEVAL SYSTEM

We are all about efficiency. An automated storage and retrieval system (ASRS or AS/RS) consists of over 2000 locations, operates at speeds over 5 Meters per second and can house over 16,000 unique finished goods. With a variety of computer-controlled systems fully automated with ERP system for automatically placing and retrieving finished goods at a moment’s notice, we are able to pick, assemble, quality check, pack and ship same day.

Total locations

Pick/pulls each per day

Open locations

SPECS

- Muratec ASRS with 2000 location inventory system

- Capable of storing 16000 unique part numbers

- Speeds up to 5 Meters per second

- Ability to pull 1080 locations per shift

- Ability to pick 1080 location per shift