Manufacturing

There's Nothing We Can't Do

Open capacity %

Machine

The ShrinkSTATION is an ideal solution for keeping the tooling and manufacturing process precise every time. It is a reliable shrink fit machine that can handle practically all sizes and types of tool holders.

SPECS

- Auto-Quench means you never touch hot toolholder

- Flexible – operates on 208V up to 480V

- Rating: 3 phase, 480V, 20A

- L x D x H: 37” x 24” x 71”

- Ship Wt. 660 lbs

- Tool change: 2-6 seconds

- Liquid cooling cycle that is 205% faster than air-cooled units

ZOLLER SMILE 600-4 TOOL PRESETTER MACHINE

Open capacity %

Machine

Equipped with all standard measuring functions for professionally presetting and measuring cutting tools.

SPECS

- Single hand operating device

- SK 50 high-precision spindle

- Consistent use of brand name products

- Robust and equipped for the shop floor

- Membrane keypad for power-activated spindle clamping and spindle indexing

- Flexible adaption to your manufacturing

- Data transmission direct to your machine control unit

METAL SAW

Open capacity %

Machines

The CS2 is one of the fastest, most accurate fully-automated cutoff saws on the market for non-ferrous extrusions. It handles materials from ¼” to 12” thick with a cutting window of 24”. The short cutting window allows a tight level of cutting accuracy. The standard back gauge supports materials from 12’ to 24’ in length. Metal Saw system is outfitted with 24’ bar feed loaders.

SPECS

- Cutting Window 24”

- Cutting Height 1/4” to 12”

- Back gauge Length 12’ to 24’

- Cut Length Range ½” minimum

- Motor 30HP, 22KW

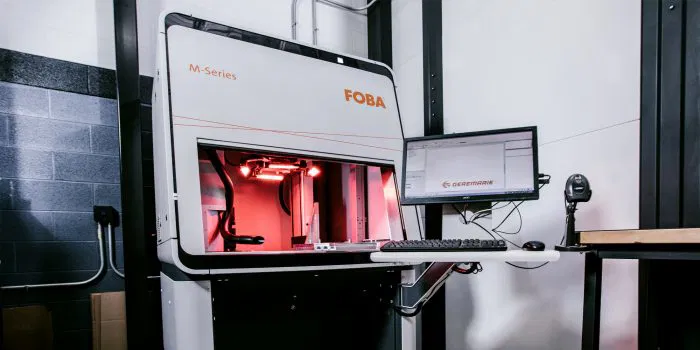

FOBA LASER MARKING SYSTEM

Open capacity %

Machine

We offer turnkey-ready and customer specific laser processing services. Our laser marking machine adapts and always allows for the most economical and optimal configuration for the application in question. A variety of loading concepts ensures optimal integration into the production environment, and axis systems can be selected based on the requirements.

SPECS

- M3000-R stations

- 2 position rotary tables

- Programmable Z-axis

- 2 position rotary table with 950 mm (M3000-R) diameter

- Flat part marking up to 10” by 30”

ZEISS ACCURA COORDINATE MEASURING MACHINE

Open Capacity %

Machine

Performance and precision are our top priorities. With its wide range of configurations, the ZEISS ACCURA measuring machine is tailored to meet our customers’ needs and budget. The modular design makes the system futureproof as it can be modified to meet changing requirements on the configuration, sensors and software. If you dream it, we can measure it.

SPECS

- Zeiss Accura II Running Calypso Software

- Fully Automated

- Offline programing capability with separate offline programming station.

- Programming routine may be created using customer supplied CAD models.

- X measuring range: 900mm

- Y measuring range: 1600mm

- Z measuring range: 800mm

- Calibrated to ISO10360

- VAST XXT Articulating Scanning Probe

- VAST Navigator technology to insure optimum scanning accuracy

- Total volume accuracy within 1.7μm

FACTORY AUTOMATION – CONVEYOR SYSTEM

Miles

Bins per Day

We have over one mile of zero pressure accumulation technology roller conveyors configured to transport all the work in process throughout the plant to each of the necessary processing stations. Once all processes are completed, they are conveyed to the integrated automatic storage and retrieval system.

SPECS

- Custom conveyor system

- Over 1.7 miles of elevated conveyors

- Fully integrated into the ERP system and process routers

- Delivers products to and from multiple departments

- Providing ultimate operating efficiency from operation to operation

KARDEX REMSTAR SHUTTLE XP AUTOMATED STORAGE AND RETRIEVAL SYSTEM

Locations

Machines

We have two self-contained inventory storage systems in the facility. The Shuttle XP vertical storage lift system from Kardex Remstar is a highly flexible solution for managing a high number of storage and retrieval applications in a wide range of ways to add to our efficiencies. The cross functional system is fully integrated to our ERP solution allowing for accurate inventory management aligned with Customer needs. The modular design of the Shuttle XP provides virtually unlimited flexibility when making the best use of various part, shelf and room heights. The unit was chosen to perfectly meet our parts capacity and height requirements.

SPECS

- Flexible adaptation to your manufacturing

- Technical data

- Shuttle XPlus

- Width 4,460 mm to 7,040 mm

- Depth 2,921 mm to 3,074 mm

- Height 3,050 mm to 20,050 mm

- Unit height pitch 100 mm increments

- Performance data

- Drive speed 250 kg/500 kg

- Vertical speed adjustable up to 1.5 m/s

- Storage/retrieval speed 0,62 m/s

- Horizontal speed adjustable up to 1.3 m/s

- Gross load 30 t per segment

- Trays

- Width 1,250 mm to 2,450 mm

- Depth 813/864 mm

- Storage space pitch 25 mm

- Tray spacing min. 75 mm

- Load up to 545 kg

- Data transmission direct to machine control unit

MURATEC AUTOMATED STORAGE AND RETRIEVAL SYSTEM

Total locations

Pick/pulls each per day

Open locations

We are all about efficiency. An automated storage and retrieval system (ASRS or AS/RS) consists of over 2000 locations, operates at speeds over 5 Meters per second and can house over 16,000 unique finished goods. With a variety of computer-controlled systems fully automated with ERP system for automatically placing and retrieving finished goods at a moment’s notice, we are able to pick, assemble, quality check, pack and ship same day.

SPECS

- Muratec ASRS with 2000 location inventory system

- Capable of storing 16000 unique part numbers

- Speeds up to 5 Meters per second

- Ability to pull 1080 locations per shift

- Ability to pick 1080 location per shift