Manufacturing

There's Nothing We Can't Do

Open capacity %

Lights out hrs. capacity

This horizontal machining center provides highly accurate, high speed machining for large parts up to 2000 pounds with integrated tooling. For heavy large parts with high production or low lot size jobs – flexible, strong, accurate, productive.

SPECS

- 800 mm square pallet

- Axis travels X: 1,400, Y: 1250, Z: 1,250 – 4 axis

- 50 Taper 12,000 RPM, 40/30 HP VAC Spindle

- 2-speed range integral motor-spindle

- 1 degree B axis rotary table

- 12 second rotary APC change (180 degree)*

- ATC: T-T : 2.0 sec, C-C: 4.4 sec.*

- 2,362 IPM rapid ( 60 meter/ min )

- 0.7 G – Maximum acceleration

- Y-axis motor bracket cooling

- Spindle head cooling

- 281 Tool matrix magazine

- 1000psi through-the-tool coolant

- 12 position pallet pool

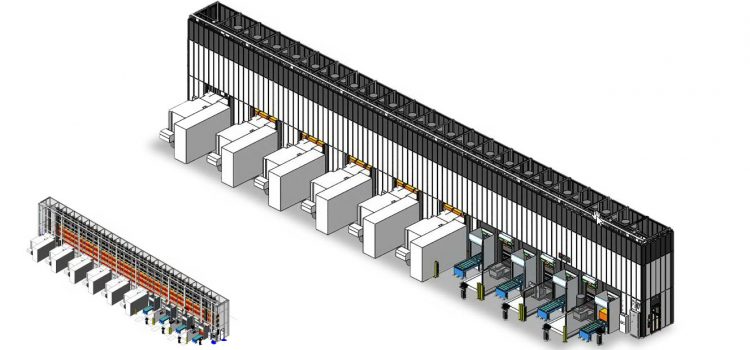

OKUMA HORIZONTAL MA600H FMS

Open capacity %

Lights out hrs. capacity

The most incredibly versatile pallet-based FMS system that integrates with six OKUMA MA-600 Horizontal machining centers, allowing up to 84 hours of true lights out manufacturing including integrated tooling, material storage and handling. . System is highly flexible and can process large variety of parts, sizes and volumes. This FMS system is the largest deployment in North America.

SPECS

- 630 mm square pallet

- Axis travels X: 1,000, Y: 900, Z: 1,000 – 4 AXIS

- 50 Taper 12,000 RPM, 40/30 HP VAC Spindle

- 2-speed range integral motor-spindle

- 1 degree B axis rotary table

- 12 second rotary APC change (180 degree)*

- ATC: T-T : 2.0 sec, C-C: 4.4 sec.*

- 2,362 IPM rapid ( 60 meter/ min )

- 0.7 G – Maximum acceleration

- Y-axis motor bracket cooling

- Spindle head cooling

- 285 Tool matrix magazines

- 1000psi through-the-tool coolant

OKUMA HORIZONTAL MB4000H FMS

Open capacity %

Lights out hrs. capacity

The most incredibly versatile pallet-based FMS system that integrates with six OKUMA MB4000 Horizontal machining centers, with integrated tooling, material storage and management, allowing up to 60 hours of true lights out manufacturing . System is highly flexible and can process a large variety and volume of small and mid-size parts.

SPECS

- 400 mm square pallet

- Axis travels X: 22.05, Y :22.05, Z:24.61 – 4 axis

- 40 Taper 15,000 RPM, 35 HP VAC Spindle

- 2-speed range integral motor-spindle

- .001 degree B axis rotary table

- 7 second rotary APC change (180 degree)*

- TC: T-T :1.0 sec, C-C: 2.3 sec.*

- 2362 IPM rapid ( 60 meter/ min )

- Y-axis motor bracket cooling

- Spindle head cooling

- 218 Tool Matrix Magazines

- 1000 psi coolant

OKUMA HORIZONTAL MB4000H PALLET ACE

Open capacity %

Lights out hrs. capacity

The most incredibly versatile pallet-based FMS system that integrates with two OKUMA MB4000 Horizontal machining centers with integrated tooling, allowing up to 48 hours of true lights out manufacturing. System is highly flexible and can process a high volume of small and mid-size parts.

SPECS

- 400 mm square pallet

- Axis travels X: 22.05, Y :22.05, Z:24.61 – 4 axis

- 40 Taper 15,000 RPM, 35 HP VAC Spindle

- 2-speed range integral motor-spindle

- .001 degree B axis rotary table

- 7 second rotary APC change (180 degree)*

- TC: T-T :1.0 sec, C-C: 2.3 sec.*

- 2362 IPM rapid (60 meter/ min )

- Y-axis motor bracket cooling

- Spindle head cooling

- 218 Tool Matrix Magazine

- 1000 psi coolant